When Critical Spares Can’t Be Trusted, Uptime is at RISK

Engineer-led vessel inventory optimization, storeroom organization, and fleet software support—built by people who sail.

Founded and led by a licensed marine engineer with 14+ years of shipboard and fleet operations experience.

Never-Lo delivers precise, efficient vessel inventory optimization led by experienced marine engineers.

Our team conducts a thorough review of all spare parts—tailored to your vessel’s operational needs—ensuring every critical component is accurately accounted for.

We inventory all applicable spares, update and reconcile shipboard software systems, and repackage and relabel items using temperature- and weather-resistant labeling designed for longevity in marine environments.

Each engagement concludes with a comprehensive findings report, including inventory status, discrepancies, and clear recommendations for follow-up actions to improve reliability, compliance, and operational readiness.

Schedule a consultation and discuss an upcoming vessel visit.

Services

Inventory Auditing

What we solve

Inaccurate or outdated shipboard inventory records

Unknown condition of critical and long-lead spares

Mismatch between physical inventory and fleet software data

Crew distrust of inventory systems due to past inaccuracies

Operational risk caused by missing, duplicated, or obsolete parts

What we deliver:

Comprehensive physical spare-parts audits conducted by licensed marine engineers

Verification of quantities, condition, criticality, and location of onboard spares

Cross-checking of physical inventory against shipboard records and fleet systems

Identification of missing, duplicate, obsolete, or incorrectly categorized items

Clear, defensible inventory data that supports maintenance planning and procurement

Findings presented in a format usable by both shipboard crews and shore teams

Inventory Auditing with Marine-Grade Repackaging and Labeling

Expert support for shipboard and fleet maintenance systems, including NSE, BassNet, Maximo, and related platforms—covering data reconciliation, system updates, inventory alignment, and post-audit reporting.

Fleet Software Support (NSE, BassNet, Maximo & Similar Systems)

What we solve:

Ghost parts, duplicate spares, and obsolete inventory

Mismatch between physical spares and fleet software

Poor packaging, labeling failures, and degraded spares

Crews who don’t trust inventory systems or processes

What we deliver:

Full physical inventory auditing of onboard spares

Condition assessment of critical and long-lead items

Repackaging of spares into heat- and weather-resistant bags suitable for harsh marine environments

Application of durable, marine-grade labels for long-term visibility, traceability, and compliance

Alignment of physical inventory with BASSnet, NSE, Maximo or similar

Clean, defensible inventory data crews can rely on under pressure

Engineer-designed storeroom layouts based on:

System criticality

Frequency of use

Emergency access requirements

Clear location and labeling standards

Packaging and labeling strategies that survive heat, humidity, and vibration

Crew orientation to ensure layouts remain sustainable

Crew Training Included:

Hands-on crew training during inventory execution

Practical instruction on:

Inventory control best practices

Proper spare handling, storage, and labeling

Correct use of fleet inventory software

Focused on real shipboard workflows, not classroom theory.

The Never-Lo Ethos

At Never-Lo, we believe that nothing critical should ever be missing, mislabeled, or misunderstood. In marine operations, accuracy is not optional—it is the foundation of safety, reliability, and performance.

We approach every vessel with the mindset of marine engineers, not auditors with clipboards. Our work is hands-on, methodical, and driven by real shipboard experience. There will never be interruption with ship going operations as our engineers travel with the vessel.

Every spare part is treated as mission-critical, every data entry as consequential, and every recommendation as a responsibility.

We are committed to precision without shortcuts—verifying physical inventory against fleet software, correcting discrepancies at the source, and ensuring spares are protected, traceable, and ready when needed. Our use of marine-grade packaging, heat- and weather-resistant labeling, and disciplined software reconciliation reflects our respect for the harsh environments vessels operate in.

Never-Lo stands for clarity, accountability, and continuity. We do not simply document problems—we resolve them, explain them, and provide practical guidance to prevent them from returning. Our reporting is transparent, our recommendations actionable, and our follow-up intentional.

Above all, we exist to support the people who keep vessels running. By delivering inventory systems crews can trust and software data they can rely on, Never-Lo helps ensure ships sail prepared—never low, never uncertain, never compromised.

About Us

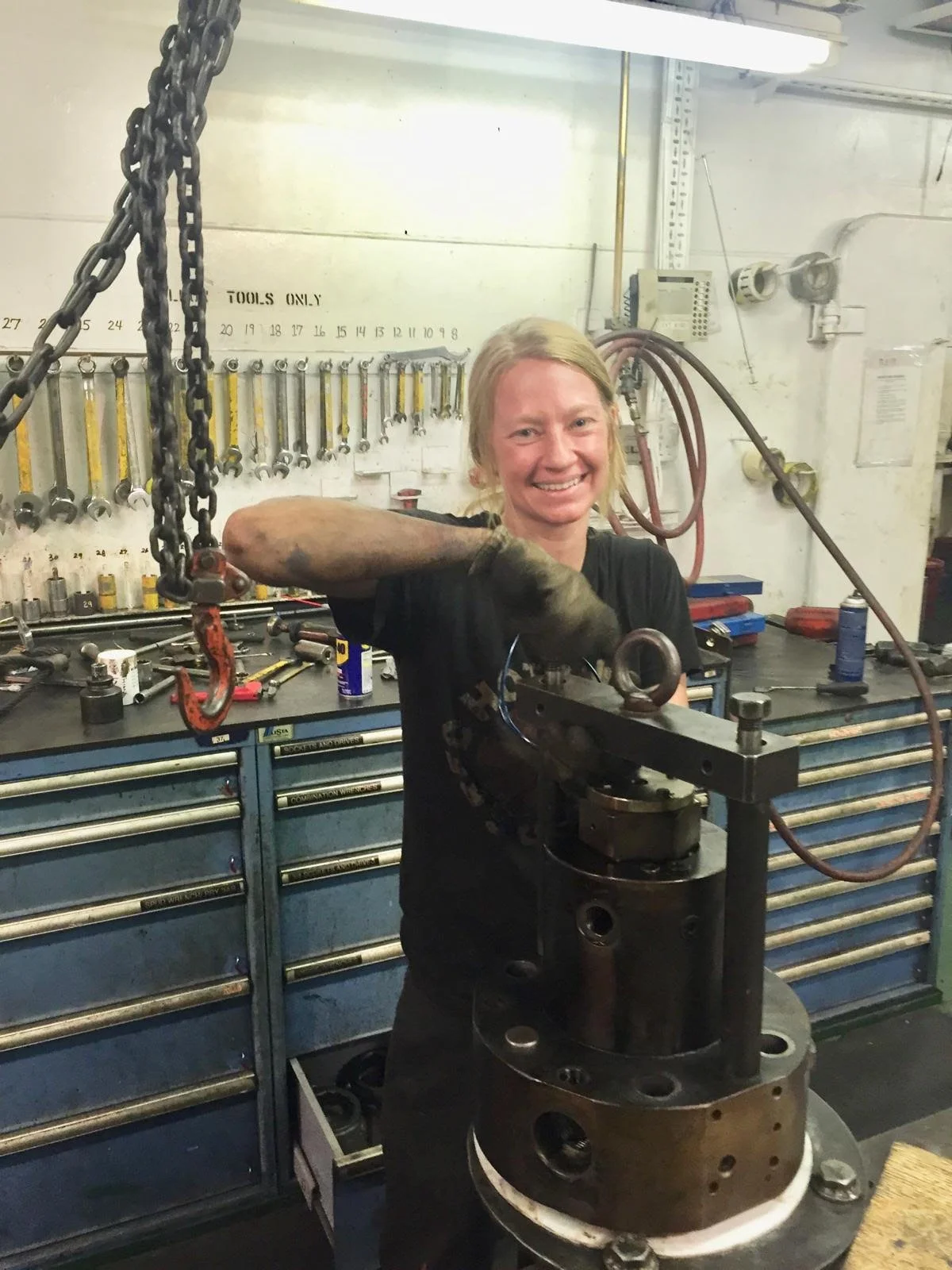

Never-Lo is a small, women-owned marine engineering company specializing in vessel inventory optimization and fleet software support. Founded and led by a practicing marine engineer, Never-Lo was created to address a common industry problem: critical spare parts and shipboard data that cannot always be trusted when they are needed most.

The company’s CEO is a First Engineer with a Bachelor’s degree in Marine Engineering and over 14 years of hands-on experience working aboard vessels and within fleet operations. Throughout her career, she has led and participated in more than 16 vessel inventory projects, developing a deep understanding of the realities crews face at sea and the operational consequences of inaccurate inventory systems.

Never-Lo brings real shipboard experience to every engagement. We do not approach inventory from a purely administrative standpoint—we approach it as marine engineers who understand how spares, systems, and software directly impact safety, reliability, and uptime. Our work bridges the gap between physical inventory and fleet software, ensuring that what exists on board accurately reflects what is recorded in systems such as NSE and Maximo.

As a small, specialized firm, Never-Lo offers a level of attention, accountability, and consistency that larger organizations often cannot. Every project is led with care, precision, and respect for the vessel and its crew. Our mission is simple: to deliver inventory systems operators can trust and vessels can rely on—never low on accuracy, never low on readiness.

Contact Us

Have questions about your vessel inventory or fleet software? Never-Lo is ready to help. Contact us to discuss your operational needs.